+86-731-85666876

Liuyang High-Tech Industrial Area, Changsha China

| Availability: | |

|---|---|

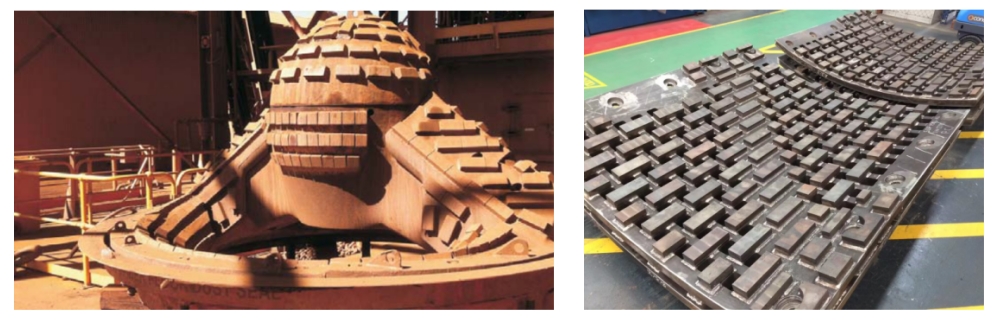

Bi - Metallic 30mm - 300mm width Wear Block is a robust wear - resistant component designed to provide protection to equipment surfaces in various industrial settings. With a width range of 30mm to 300mm, these blocks offer flexibility in covering different surface areas. The bi - metallic composition, combining a wear - resistant alloy and a strong base metal, ensures they can withstand heavy abrasion and impact. They are essential for extending the service life of equipment in industries such as mining, construction, and manufacturing.

Wide Range of Widths: The 30mm - 300mm width options allow for covering large or small equipment surfaces as needed, providing comprehensive wear protection. This versatility makes them suitable for various applications.

High Impact Resistance: The base metal's toughness enables the wear blocks to absorb impact forces without breaking, making them ideal for use in equipment that handles heavy or bulky materials.

Excellent Wear Resistance: The wear - resistant alloy on the surface ensures long - term protection against abrasion, reducing the need for frequent replacements and lowering maintenance costs.

Consistent Quality: Manufactured using strict quality control processes, each wear block meets high standards of performance and reliability, ensuring consistent results in different applications.

Compatibility with Different Surfaces: They can be attached to various materials such as steel, cast iron, and aluminum, making them adaptable to different equipment types.

In the mining industry, these wear blocks are used to protect the surfaces of ore conveyors, crushers, and grinding mills. In construction, they are applied to the buckets of bulldozers, the blades of graders, and the beds of dump trucks. Manufacturing facilities use them to safeguard production lines, especially in areas where materials are transported or processed. They are also used in waste management equipment to handle the abrasive nature of garbage and recyclables.

Q: What is the maximum length available for these wear blocks?

The length can be customized based on customer requirements. Manufacturers can produce wear blocks of various lengths within reasonable limits to fit specific equipment dimensions.

Q: How long does it take to replace these wear blocks?

The replacement time depends on the number of blocks, the mounting method, and the accessibility of the equipment. With proper tools and trained personnel, it can typically be done within a few hours.

Q: Are there any environmental restrictions on the use of these wear blocks?

They are generally suitable for use in most environments, including outdoor and indoor settings. However, in extremely corrosive environments, additional protective coatings may be required.

Q: Can they be reused after being removed from one piece of equipment?

It depends on their condition. If they are still in good shape with minimal wear, they can be reused on other equipment that requires similar wear protection. However, it's important to inspect them thoroughly before reuse.

Rectangular bars are available in thicknesses ranging from 25mm to 100mm, widths from 25mm to 300mm and in varying lengths. Popular for use in rock box protection, impact areas and transfer points, bars can be provided with Nelson studs with size and location to suit.